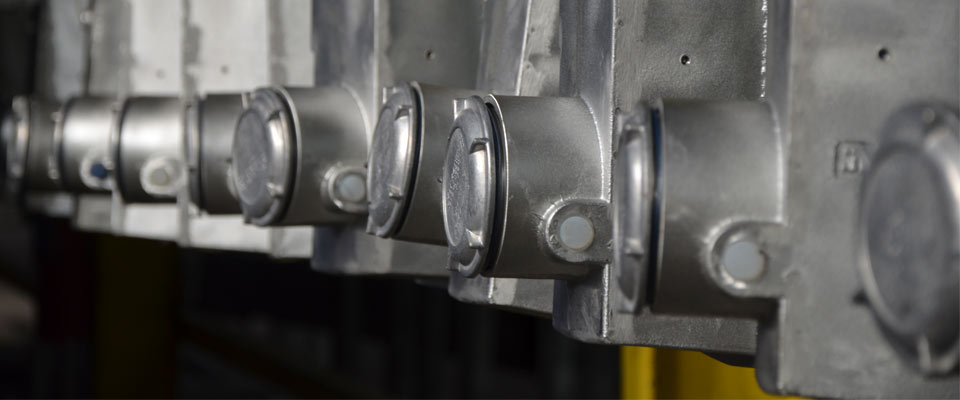

Our automatic powder coat line is designed to accommodate large volume production.

The line is capable of running parts up to 2 ft. wide X 7 ft. 8 in. X 6 ft. 6 in. in size.

It is designed as a looped conveyor system. Racked or hung parts move first into a wash system, followed by a dry-off oven, then into a spray booth, where powder is applied via 12 automatic spray heads (or manually) as the parts pass through. The line is capable of reclaiming powder for reuse. The parts continue through a gas convection cure oven. After completing the cycle, the parts are removed and packaged for shipment.

Our system is capable of powder coating at speeds up to 22 foot per minute which makes it suitable and cost-effective for almost any industrial use.